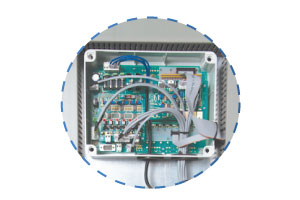

DPC, acronym for Decanter Process Controller, is the electronic card designed, built and programmed from CBB Decanter s.r.l. for the management and control of separation process of 2 or 3 phases contained in a product of wastewater and/or industrial and/or food origin through the decanter.

Entirely programmed in Assembly language, it optimizes at the best the process of separation checking and managing all the variables that affected the process and possible alarms. In this way, it allows to work automatically and with security taking maximum advantages of all potentiality of CBB decanter.

Inside, there is the know-how of a twenty-year experience in the processes of sludge separation that allows us to satisfy the most of the requests and of necessities of the customer. Moreover, it is able to converse with other electronic cards (PLC, PC…) through Modbus protocol.

MAIN CHARACTERISTICS OF DPC (Decanter Process Controller)

DPC is a very flexible electronic card and in the specific it is able to manage:

- Bowl speed;

- Screw speed;

- Differential speed screw/belt;

- Hydraulic pressure;

- Electrical motors absorption;

- Levels and oil temperature;

- Bearings temperature;

- Vibration level;

- Bearing greasing;

- Hydraulic pump;

- Decanter status;

- Work mode;

- Alarms;

- Starting phase;

- Working phase;

- Washing phase;

- Automatic regulation of sludge and polymer pumps;

- Sludge and polymer capacity;

- Sludge preparation tank;

- Polymer preparation tank;

- Sludge evacuation screw;

- communication with Modbus RS-485 or TCP/IP protocol;

- Remote assistance;

- Touch screen;

- Possible customer questions;

INNOVATION OF DPC CONTROLLER (DECANTER PROCESS CONTROLLER)

Need more information ?

One of our representatives will be at your disposal, ready to listen.