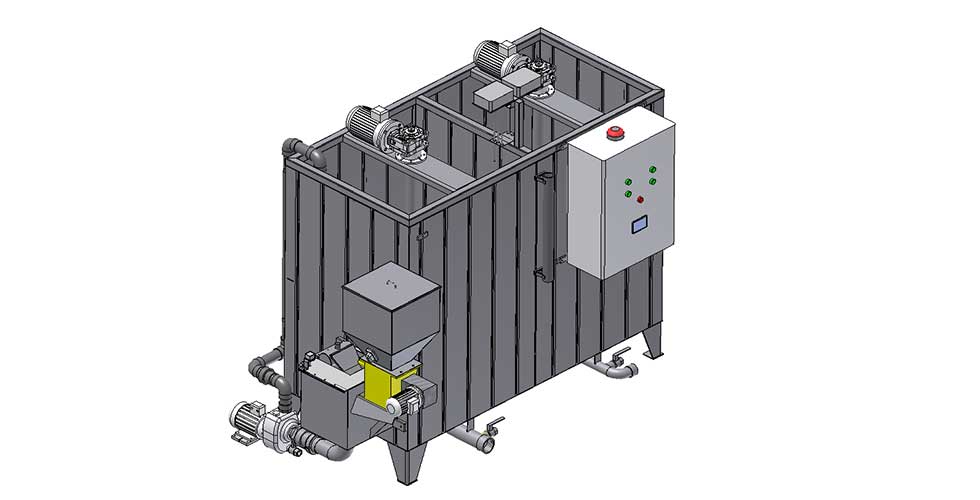

CBB POLYMER STATIONS are conceived for the preparation of a polielectrolite solution to use along with a centrifugal decanter in order to ease the separation of 2 or 3 phases contained in a product of wastewater and/or industrial origin.

Solution is prepared mixing the right percentage of liquid and/or powder polymer with water.

CBB Decanter designs and realizes mainly two types of polymer stations: powder and liquid automatic polymer stations and liquid automatic polymer stations.

7 REASONS TO CHOOSE A CBB DECANTER POLYMER STATION:

- Working cycle managed automatically by a dedicated electronic card

It allows to work in security taking maximum advantage of the potentiality of the machine; - Opposed position of loading points and picking from the tank

It guarantees homogeneity of prepared polymer solution; - Agitators, mixer and loading pumps

They guaranteed an optimal mixing between polymer and water; - Polymer saving

Assured by perfect mixing, solution homogeneity and presence of dedicated electronic card; - Inductive sensors for liquid levels measurement controlled by electronic card

They guarantees precision of measurement with presence of material deposit; - Micro doser in polyurethane to ration powder polymer

It limits formation of grains due to humidity and condensation; - Too much full pipe

Prevent leackage of solution in case of possible anomalies;

CBB DECANTER POLYMER STATION PRESENTATION

Discover types of DECANTER CBB our production.

Also, you can find out the characteristics of the DECANTER CBB of our production or configure YOUR DECANTER on line.

Download PRODUCT PDF LIST of the DECANTER CBB.

Need more information ?

One of our representatives will be at your disposal, ready to listen.